The limit of my suspension knowledge is 'get bilsteins and use bigger swaybars'.

How do you go about choosing a spring rate rate for coilovers (240 with a v8)? Is there a mathematical way to go about making an educated choice?

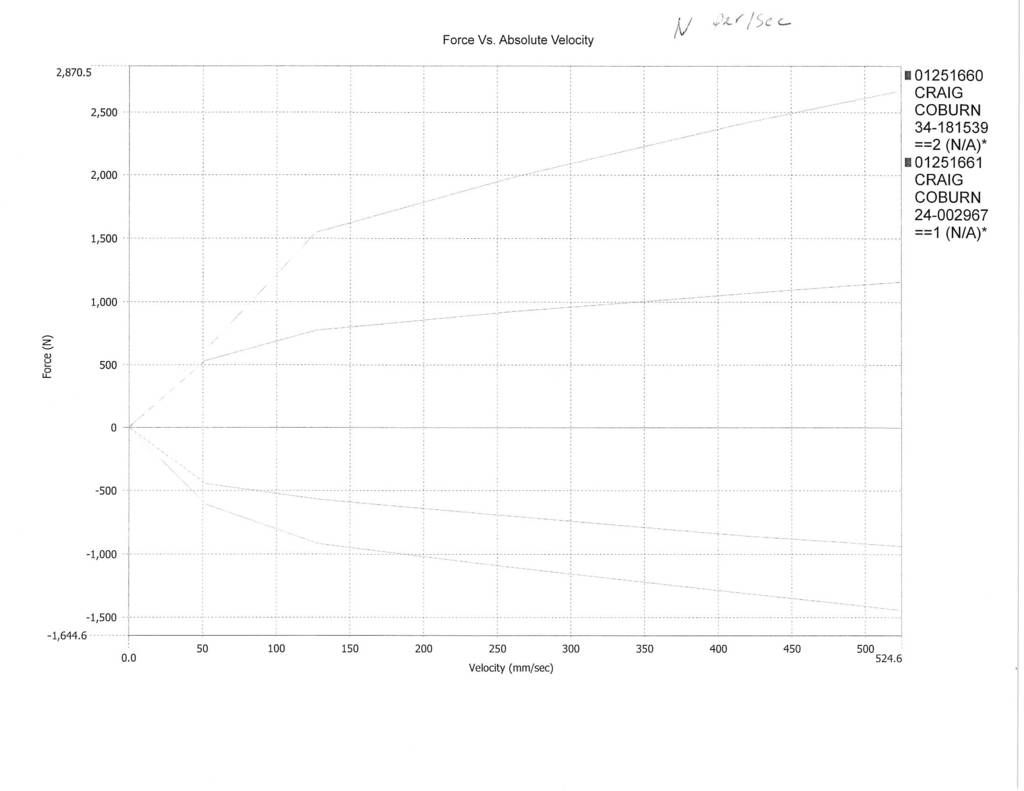

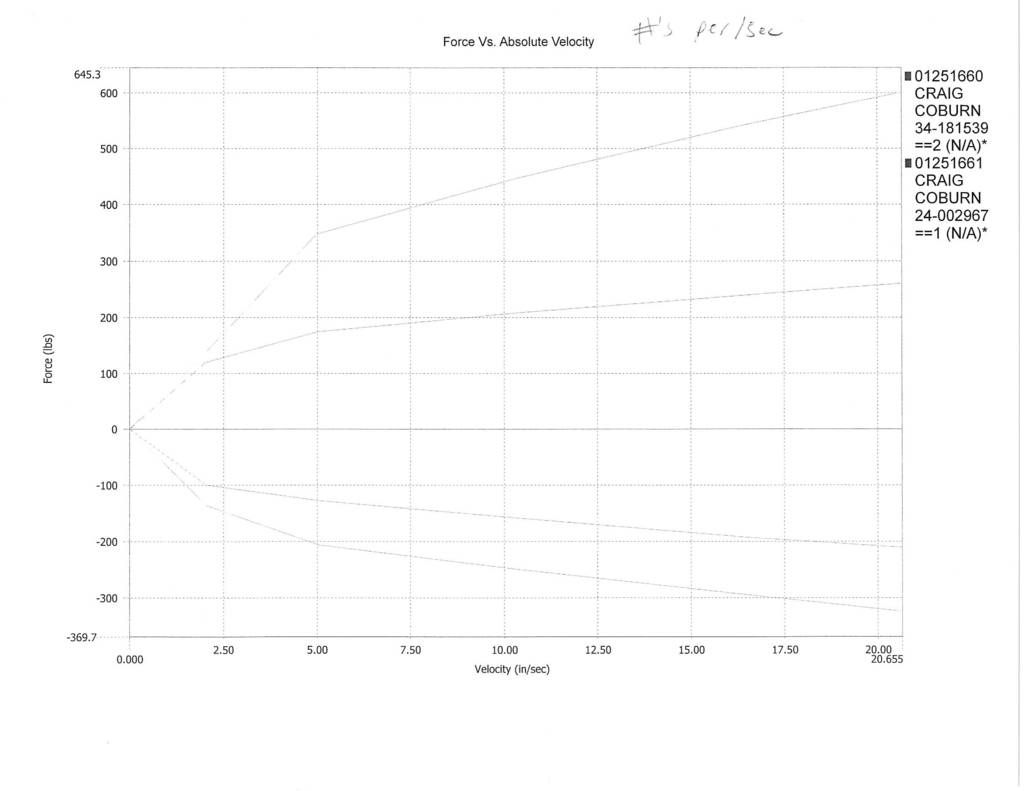

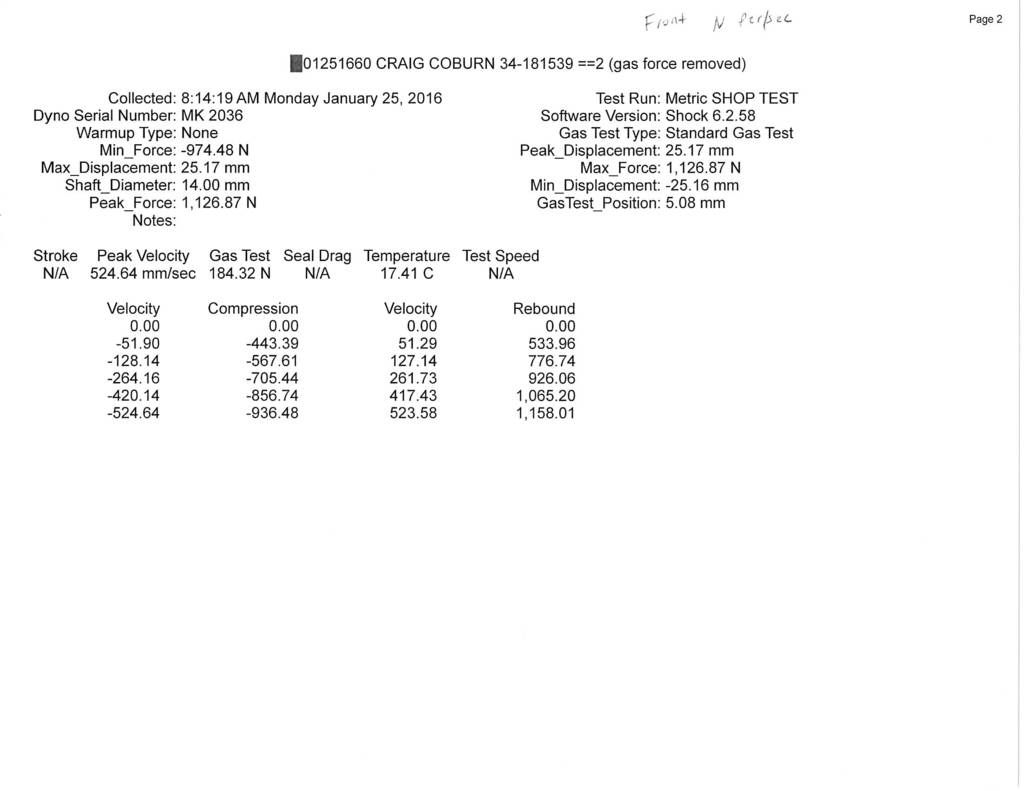

In a related note, how do you best determine what valving is required for the dampers to go along with your choice of springs? I see you guys quoting valving numbers for certain springs and I see people talking about certain spring rates not working well with a certain shock. I really don't understand what you're talking about.

If you could offer some advice or perhaps reference texts I'd appreciate it.

My current setup uses 325lb springs with bilstein hd struts up front (not shortened) along with 250lb rear springs and chevy 4x4 bilstein hd's.

How do you go about choosing a spring rate rate for coilovers (240 with a v8)? Is there a mathematical way to go about making an educated choice?

In a related note, how do you best determine what valving is required for the dampers to go along with your choice of springs? I see you guys quoting valving numbers for certain springs and I see people talking about certain spring rates not working well with a certain shock. I really don't understand what you're talking about.

If you could offer some advice or perhaps reference texts I'd appreciate it.

My current setup uses 325lb springs with bilstein hd struts up front (not shortened) along with 250lb rear springs and chevy 4x4 bilstein hd's.