-

Hello Guest, welcome to the initial stages of our new platform!

You can find some additional information about where we are in the process of migrating the board and setting up our new software hereThank you for being a part of our community!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

740 In tank sending unit

- Thread starter colgate41

- Start date

FreeEMSFred

New member

- Joined

- Nov 2, 2009

- Location

- Kiwiland

Don't forget to steryli[s|z]e these tools/parts you're getting, Colgate 41, right now is a bad time in history to be receiving used goods from other, especially in NY, Spain, or Italy.

I'm glad mine's not rusty like yours, but instead, it's awfully dusty - the car must have been used on gravel/metal roads for half its life:

I assume that hose clamp around the nut is not factory and that someone chucked it on there because they broke the nut or felt it wasn't tight enough/sealing well enough/etc - so I probably have some fun times ahead, and i can't get at my spare tank/pump/parts right now due to being 1.5 weeks into a 4 week hard lock down - essential travel only.

Re psi, the regulator takes care of that, if it's not faulty, you'll get the correct pressure, and if the pump can't produce it you'll get no or insufficient flow, but all EFI pumps can produce enough to overwhelm a factory rail pressure regulator. Or did you mean the hoses? If so, 50psi minimum, usually they're rated much much higher than that. If it's before the main pump then low pressure hose will be fine. If it's after the main pump and before the regulator good high pressure hose is needed. Return line low pressure hose is fine, until the end in the tank blocks one day

I'm glad mine's not rusty like yours, but instead, it's awfully dusty - the car must have been used on gravel/metal roads for half its life:

I assume that hose clamp around the nut is not factory and that someone chucked it on there because they broke the nut or felt it wasn't tight enough/sealing well enough/etc - so I probably have some fun times ahead, and i can't get at my spare tank/pump/parts right now due to being 1.5 weeks into a 4 week hard lock down - essential travel only.

Re psi, the regulator takes care of that, if it's not faulty, you'll get the correct pressure, and if the pump can't produce it you'll get no or insufficient flow, but all EFI pumps can produce enough to overwhelm a factory rail pressure regulator. Or did you mean the hoses? If so, 50psi minimum, usually they're rated much much higher than that. If it's before the main pump then low pressure hose will be fine. If it's after the main pump and before the regulator good high pressure hose is needed. Return line low pressure hose is fine, until the end in the tank blocks one day

ZVOLV

<Master Tech>

- Joined

- Nov 19, 2002

- Location

- California

I would probably drop the tank and do the work on the bench and be ready to source some parts.

Don't forget to steryli[s|z]e these tools/parts you're getting, Colgate 41, right now is a bad time in history to be receiving used goods from other, especially in NY, Spain, or Italy.

I'm glad mine's not rusty like yours, but instead, it's awfully dusty - the car must have been used on gravel/metal roads for half its life:

I assume that hose clamp around the nut is not factory and that someone chucked it on there because they broke the nut or felt it wasn't tight enough/sealing well enough/etc - so I probably have some fun times ahead, and i can't get at my spare tank/pump/parts right now due to being 1.5 weeks into a 4 week hard lock down - essential travel only.

Re psi, the regulator takes care of that, if it's not faulty, you'll get the correct pressure, and if the pump can't produce it you'll get no or insufficient flow, but all EFI pumps can produce enough to overwhelm a factory rail pressure regulator. Or did you mean the hoses? If so, 50psi minimum, usually they're rated much much higher than that. If it's before the main pump then low pressure hose will be fine. If it's after the main pump and before the regulator good high pressure hose is needed. Return line low pressure hose is fine, until the end in the tank blocks one day

I would take a mountain of dust any day over this north east rust! At some point in the cars life (I've owned it for almost 15 years now) it had a pretty serious undercoating which has helped with some things but yeah, this sending unit is a mess. I already broke one of the elbows off the sending unit itself trying to wiggle a hose off. Working on rusty cars I knew this was going to happen so I did get a working sending unit from another member and that's on its way to me.

The psi I was talking about was just for the 3 hoses that come off the sending unit. I'm trying to figure out their OD but this kind of thing, I always mess up (getting the correct size/type).

In reading and researching about this part of the car and the sending unit, I actually believe that big hose clamp on your sending unit nut is factory believe it or not. I think this was added to the 940/60 cars as just a failsafe. I could be wrong but that's what I read.

Thanks for the info and replying. The more I know, the less I can mess up

I would probably drop the tank and do the work on the bench and be ready to source some parts.

I was thinking that, even with the correct tool on order. I have a feeling since the car sat for a bit and with all the rust I'm knocking loose that dropping the tank might be worth it. I have to take a better look at it today and see what's involved and how many rusty bolts I have to deal with and if It's even a battle worth fighting.

Also, once this is all done I might hit everything with a some sort of coating to protect from rust. Anyway have any suggestions?

hiperfauto

The Librarian

- Joined

- Nov 18, 2011

- Location

- So Cal

Skandix doesn't list the size of the small vent hose but they do show the sizes of the other 2.

https://www.skandix.de/en/spare-parts/body/body-parts/fuel-tank-filling/breather-hose-fuel-tank-metre/1045180/

https://www.skandix.de/en/spare-parts/engine/fuel-mixture-formation/fuel-supply-system/fuellines-and-accessories/fuel-hose-75-mm/1008322/

https://www.skandix.de/en/spare-parts/engine/fuel-mixture-formation/fuel-supply-system/fuellines-and-accessories/fuel-hose-95-mm/1008323/

https://www.skandix.de/en/spare-parts/body/body-parts/fuel-tank-filling/breather-hose-fuel-tank-metre/1045180/

https://www.skandix.de/en/spare-parts/engine/fuel-mixture-formation/fuel-supply-system/fuellines-and-accessories/fuel-hose-75-mm/1008322/

https://www.skandix.de/en/spare-parts/engine/fuel-mixture-formation/fuel-supply-system/fuellines-and-accessories/fuel-hose-95-mm/1008323/

2manyturbos

Moderator

- Joined

- Mar 8, 2003

- Location

- Monroe, OR USA

I was thinking that, even with the correct tool on order. I have a feeling since the car sat for a bit and with all the rust I'm knocking loose that dropping the tank might be worth it. I have to take a better look at it today and see what's involved and how many rusty bolts I have to deal with and if It's even a battle worth fighting.

Also, once this is all done I might hit everything with a some sort of coating to protect from rust. Anyway have any suggestions?

Judging from your pictures, I would leave the tank in place. The straps attach to a bracket at the rear of the tank that has long threaded studs. There is also a steel bracket at the front of the tank that attaches with 8mm bolts. I would bet removing the tank will be like opening Pandora's box. Out here, I've done that more than once to work on an in tank pump/sending unit issue. I've done so many of these I just leave the tank in place now. It's much faster. You have to pull the sending unit out of the tank about 1-2 inches, then, rotate it 180 degrees counter clockwise in order to get it to come out through the hole in floor of the car. Get ready for a lot of cussin'. If the idiots at Volvo had made that access hole one inch bigger in each direction, the job would be a cake walk. It is barely possible even if you know what you are doing.

Judging from your pictures, I would leave the tank in place. The straps attach to a bracket at the rear of the tank that has long threaded studs. There is also a steel bracket at the front of the tank that attaches with 8mm bolts. I would bet removing the tank will be like opening Pandora's box. Out here, I've done that more than once to work on an in tank pump/sending unit issue. I've done so many of these I just leave the tank in place now. It's much faster. You have to pull the sending unit out of the tank about 1-2 inches, then, rotate it 180 degrees counter clockwise in order to get it to come out through the hole in floor of the car. Get ready for a lot of cussin'. If the idiots at Volvo had made that access hole one inch bigger in each direction, the job would be a cake walk. It is barely possible even if you know what you are doing.

You sir, have sold me on leaving well enough alone. I?ve opened Pandora?s box a few times with various cars and if it ain?t broke...

Thanks for the input. I?m going to leave it in place and just curse my day away but I?ll

Get it done.

Otto Mattik

board member

- Joined

- Dec 24, 2015

- Location

- Upper Midwest more or less

I was thinking that, even with the correct tool on order. I have a feeling since the car sat for a bit and with all the rust I'm knocking loose that dropping the tank might be worth it. I have to take a better look at it today and see what's involved and how many rusty bolts I have to deal with and if It's even a battle worth fighting.

Also, once this is all done I might hit everything with a some sort of coating to protect from rust. Anyway have any suggestions?

As far as rust goes, a product called OSPHO is one of(if not the best?) products for rust conversion, that I've evr used. *DON'T get that schnitzell in your face/eyes, experiment on a test area*

Try ACE Hardware or one of the vendors listed in their link(if you search ACE use SKYCO).

Marine Enterprises & Supplies, Inc.

24 young Road

Katonah, NY 10536

https://www.ospho.com/index.htm

Last edited:

FreeEMSFred

New member

- Joined

- Nov 2, 2009

- Location

- Kiwiland

Yep, agreed, and hate to do this to you, but:I would take a mountain of dust any day over this north east rust!

Cleaned up super easy with just the surface cleaner spray (surfactants) and a gentle hose down - increasing the pressure/hosing didn't help more, the last remnants were adhered to the tar underseal

Interesting! Could easily be right, you can see that dust had not been disturbed in quite a long time. I actually have full receipts for this car, unlike the others, so I could go through and check I guess, but not sure I can be bothered. A quick image search without bias showed most of them having it present and the ones that didn't likely older models. CoolIn reading and researching about this part of the car and the sending unit, I actually believe that big hose clamp on your sending unit nut is factory believe it or not. I think this was added to the 940/60 cars as just a failsafe. I could be wrong but that's what I read.

MistrThou

Masked Moogle

- Joined

- Oct 8, 2004

- Location

- Janesville, WI

I've been through this... twice.

The second time, I replaced the sending unit base (that gets held to the car) with a unit from a 95 Volvo 940. At the same time I upgraded my in tank pump to high pressure and ran a hose directly to the barb on the fuel filter. Very delicately, you can use a razor blade to remove the hose from the fitting and you can put new hose on the banjo barb and use a hose clamp.

I ran new hose from in tank to fuel filter, generic stuff from a hardware store rated high pressure fuel injection hose.

I used a side cutters to remove all old hose clamps and gingerly separated the fuel hose filler tube and return lines to put on new unit. Plan on all brand new stainless steel hose clamps. Get the nice pinch type ones, not the small cheapo ones. They fail.

In order to use a newer sending unit base, I had to take the sending unit off of the old unit. I had to cut the wires and re-solder them as the impedence on the fuel gauges is different.

I didn't take many pictures... Here's what I do have though.

My original:

Rotted out, removed from tank:

My frankensender:

The second time, I replaced the sending unit base (that gets held to the car) with a unit from a 95 Volvo 940. At the same time I upgraded my in tank pump to high pressure and ran a hose directly to the barb on the fuel filter. Very delicately, you can use a razor blade to remove the hose from the fitting and you can put new hose on the banjo barb and use a hose clamp.

I ran new hose from in tank to fuel filter, generic stuff from a hardware store rated high pressure fuel injection hose.

I used a side cutters to remove all old hose clamps and gingerly separated the fuel hose filler tube and return lines to put on new unit. Plan on all brand new stainless steel hose clamps. Get the nice pinch type ones, not the small cheapo ones. They fail.

In order to use a newer sending unit base, I had to take the sending unit off of the old unit. I had to cut the wires and re-solder them as the impedence on the fuel gauges is different.

I didn't take many pictures... Here's what I do have though.

My original:

Rotted out, removed from tank:

My frankensender:

ZVOLV

<Master Tech>

- Joined

- Nov 19, 2002

- Location

- California

I use a lift and a hydraulic jack to drop fuel tanks. Doing it at home won't be as easy. I honestly haven't dropped a 740 tank. Rusty mouting hardware could be a big hurdle, but I also don't like squeezing into trunks or cargo area.

A hammer and a flathead work well for knocking that big nut loose, usually.

A hammer and a flathead work well for knocking that big nut loose, usually.

I use a lift and a hydraulic jack to drop fuel tanks. Doing it at home won't be as easy. I honestly haven't dropped a 740 tank. Rusty mouting hardware could be a big hurdle, but I also don't like squeezing into trunks or cargo area.

A hammer and a flathead work well for knocking that big nut loose, usually.

Yeah I have the hammer and flat head a quick attempt but it was not budging so I rented a tool from member here. Hopefully that makes it easy.

I?m not dropping the tank anymore. I?ve thought better about it.

2manyturbos

Moderator

- Joined

- Mar 8, 2003

- Location

- Monroe, OR USA

ZVOLV is in California. He thinks rust is that orange color in the chips in his paint. He’s never seen real rust.

ZVOLV is in California. He thinks rust is that orange color in the chips in his paint. He?s never seen real rust.

ZVOLV

<Master Tech>

- Joined

- Nov 19, 2002

- Location

- California

I've worked on out-of-state vehicles and even cars that live near the beach get rusty from the salty breeze.

On stuff that's too rusty, it just gets cut it out and replaced.

I'm enjoying an ocean breeze right now. Ahhhhh

On stuff that's too rusty, it just gets cut it out and replaced.

I'm enjoying an ocean breeze right now. Ahhhhh

Ok, I got the old sending unit out thanks in large part to hiperfauto for renting me the correct tool. Put the tool on, gave it a good push and broke it free. Thank god it's a plastic tank and nut or I don't know what I would have done!

Anyway, I got the old sending unit out and it is in bad shape. The used part I got from white855t is in like new shape compared to the one in my car and I have a new (few years old) in tank pump ready to go. I have a few questions now...

I was going to try and re-use the fuel hose that connects to the in-tank pump but when I removed it and was inspecting it, it snapped in half. So...I need a new one but can't seem to find one on the normal Volvo sites I order parts from. Any ideas?

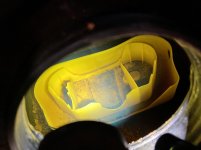

When I look into the tank, I see a lot of rust/sediment in the area where I'm guessing the sending unit sits and also at the bottom of the tank itself. I've added some photos of it. Should I be worried about that considering I'm installing a new in tank pump/sock and new fuel filter and main pump? I don't want those new parts to get all clogged up due to the crap in the tank.

In one of the photos, I've circled the part in question, I have no idea what it is or if it's somehow supposed to be connected to the sending unit. Any ideas? Its attached to the underside of the trunk on the right side.

Lastly, on the "new" sending unit, I've circled a wire that is fused together. I'm not sure if this is supposed to go anywhere or just leave it be.

Anyway, It was a good day with progress made. The right tool for the job sure does help.

Anyway, I got the old sending unit out and it is in bad shape. The used part I got from white855t is in like new shape compared to the one in my car and I have a new (few years old) in tank pump ready to go. I have a few questions now...

I was going to try and re-use the fuel hose that connects to the in-tank pump but when I removed it and was inspecting it, it snapped in half. So...I need a new one but can't seem to find one on the normal Volvo sites I order parts from. Any ideas?

When I look into the tank, I see a lot of rust/sediment in the area where I'm guessing the sending unit sits and also at the bottom of the tank itself. I've added some photos of it. Should I be worried about that considering I'm installing a new in tank pump/sock and new fuel filter and main pump? I don't want those new parts to get all clogged up due to the crap in the tank.

In one of the photos, I've circled the part in question, I have no idea what it is or if it's somehow supposed to be connected to the sending unit. Any ideas? Its attached to the underside of the trunk on the right side.

Lastly, on the "new" sending unit, I've circled a wire that is fused together. I'm not sure if this is supposed to go anywhere or just leave it be.

Anyway, It was a good day with progress made. The right tool for the job sure does help.

Attachments

lummert

Active member

- Joined

- Jan 11, 2008

- Location

- Portland IN

Submerse the pump in liquid of some sort in a container, attach fuel hose routed back into same container. Connect 12 volts and a ground wire. Pump should pump liquid back into container provided the wires are connected correctly.